Cassava is a perishable product. It will begin to rot within 3 to 4 days of the harvest. Hence, quick and effective processing of the same is necessary. You’ll find cassava generally processed into either chips, flour or starch. For this purpose, there are different types of cassava processing machinery. To know more about the different cassava processing plant equipment, read on.

What are the Different Types of Cassava Processing Plant Equipment?

1. Cassava Chips Processing

Cassava chips are used for feeding animals. With the help of the chip processing machine, you can easily get it processed. When the cassava chips are processed to prepare alcohol, along with the simple chip processor, the industries also use cleaners, peelers and dryers. The chip processing machines can be adjusted per the cassava slices’ thickness. Industries use large-scale chip processing machines for handling 7 to 8 tons of cassava chipping per hour.

2. Cassava Garri Processing

Cassava garri is the granular form of dry and crispy cassava powder which is generally made from the roots of the cassava which is mashed, fermented and divided into small pieces. For garri processing, grater, fryer, cleaner, washer, peeler, and hydraulic press must be present in the machine being operated in the food processing industry.

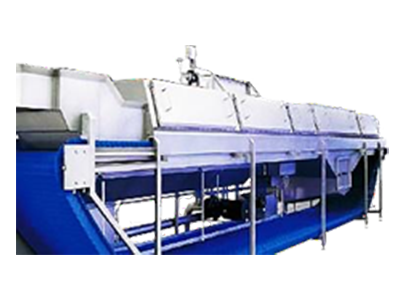

3. Cassava Flour Processing

For high-quality cassava flour, wet technology is used in the machines. The process involves cleaning the cassava slices, washing and peeling them, then desanding, drying and finally creating the fine flour specks of dust. The cost of this machine depends on the capacity of the cassava being processed into flour. These machines are usually either made of carbon steel or have stainless steel options.

4. Cassava Starch Processing

They are ergonomically built machines for cassava starch processing. The starch processing equipment functions in three phases. Firstly, the raw slices of cassava are cleaned with a cleaning solution. Then, the scratch is extracted from the slices. Finally, the extracted starch is dried. To complete this process, the machines generally have components like a paddle washer, hydrocyclone system, peeler centrifuge, flash dryer, centrifugal sieve and fine fibre sieve.

For cassava Processing Plant Equipment, contact Gem Allied Industries Pvt Ltd (Gem Foodtech). We specialise in manufacturing and exporting highly advanced cassava processing machineries. Our machines are designed to meet all types of production requirements of cassava flour and chip processing. Contact us for more details.