Best Quality Cassava Processing Plant Equipment

GEM Foodtech is a leading manufacturer of cassava processing plants. For the industry’s best cassava processing plant, we use the best technologies. Our range of cassava processing plant equipment are manufactured keeping the functional aspects of the machine in mind. We have a range of industrial customers, who check many parameters before buying the cassava processing plant.

Our motive is to use the equipment accordingly so that we can satisfy the needs of every industrial customer knocking at our doors.

Some of the important cassava processing plant equipment that we manufacture are:

- Dry sieve

- Paddle washing machine

- Rasper

- Flash dryer

- Peeler centrifuge

- Hydrocyclone station

- Centrifuge sieve

We build every cassava processing machine keeping the aesthetics of the machine in mind. Buy from us and get guaranteed quality and function from the machines.

YAM / CASSAVA PROCESSING PLANT EQUIPMENT

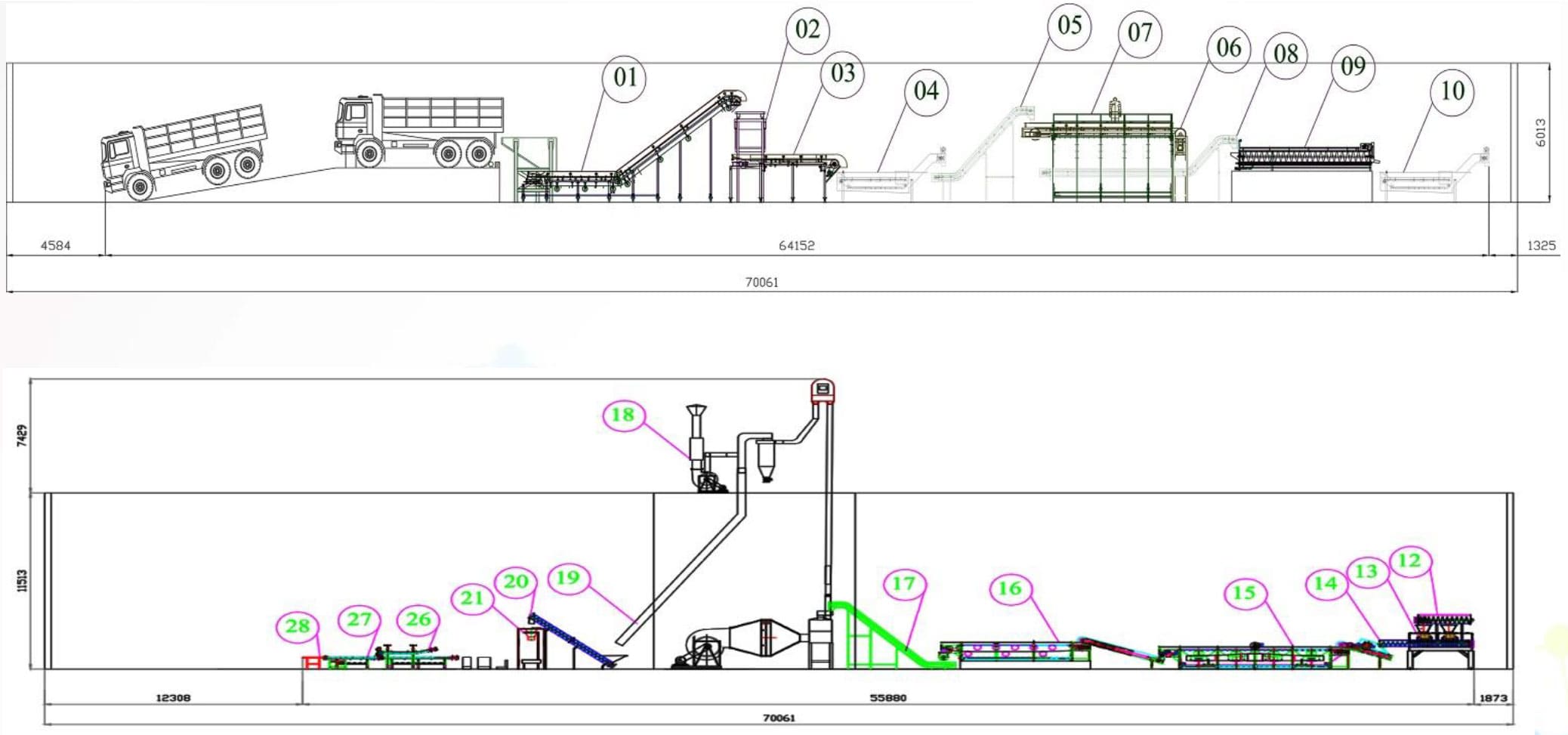

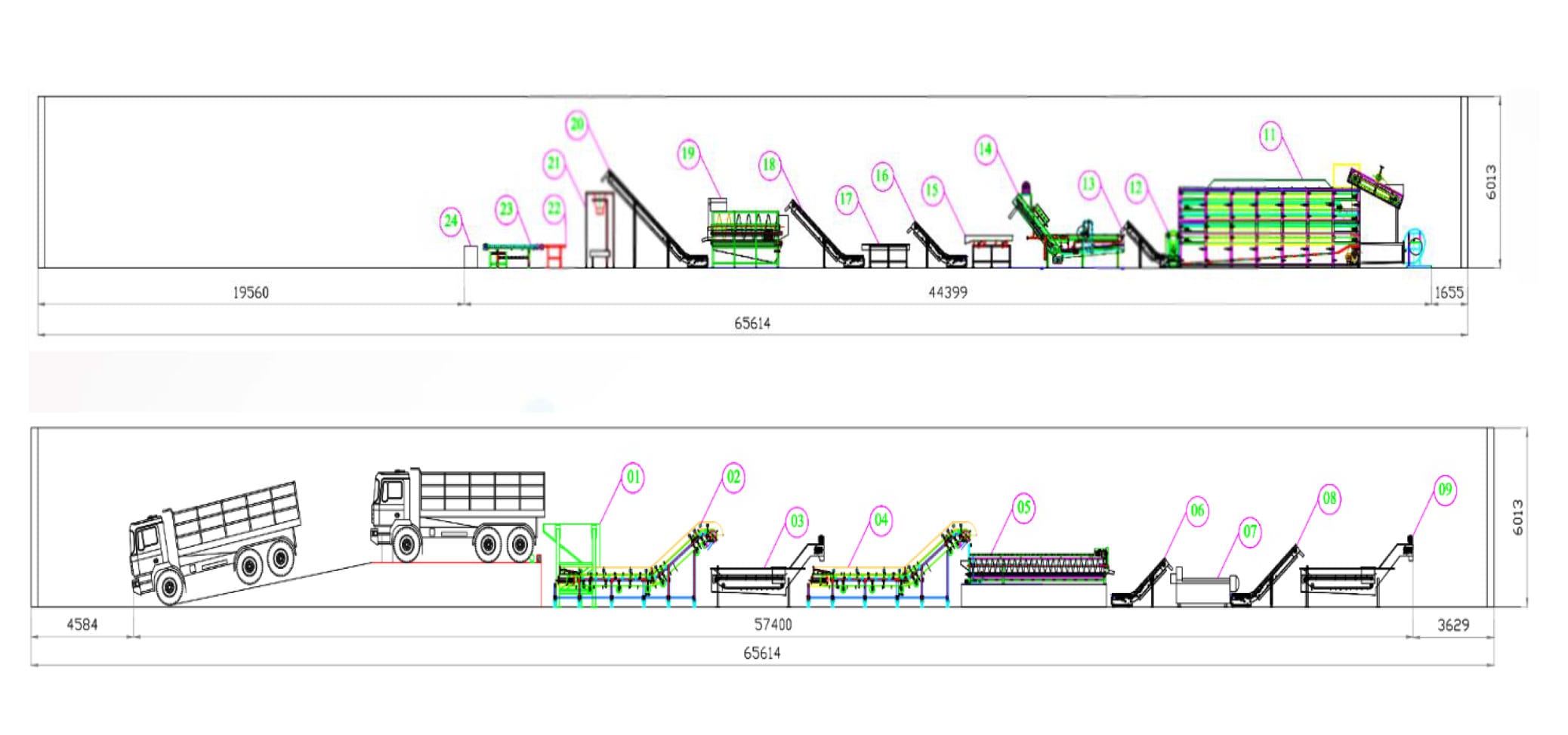

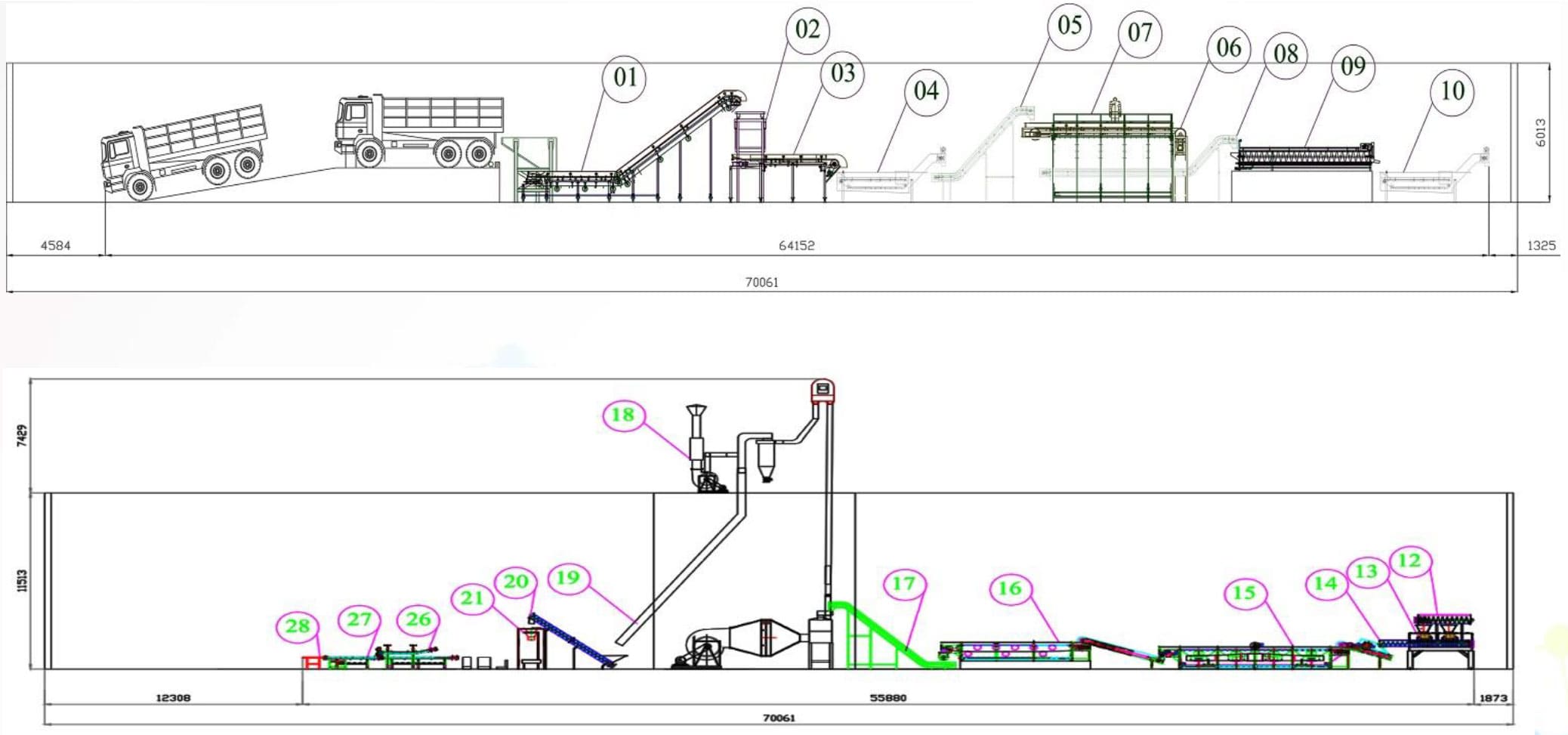

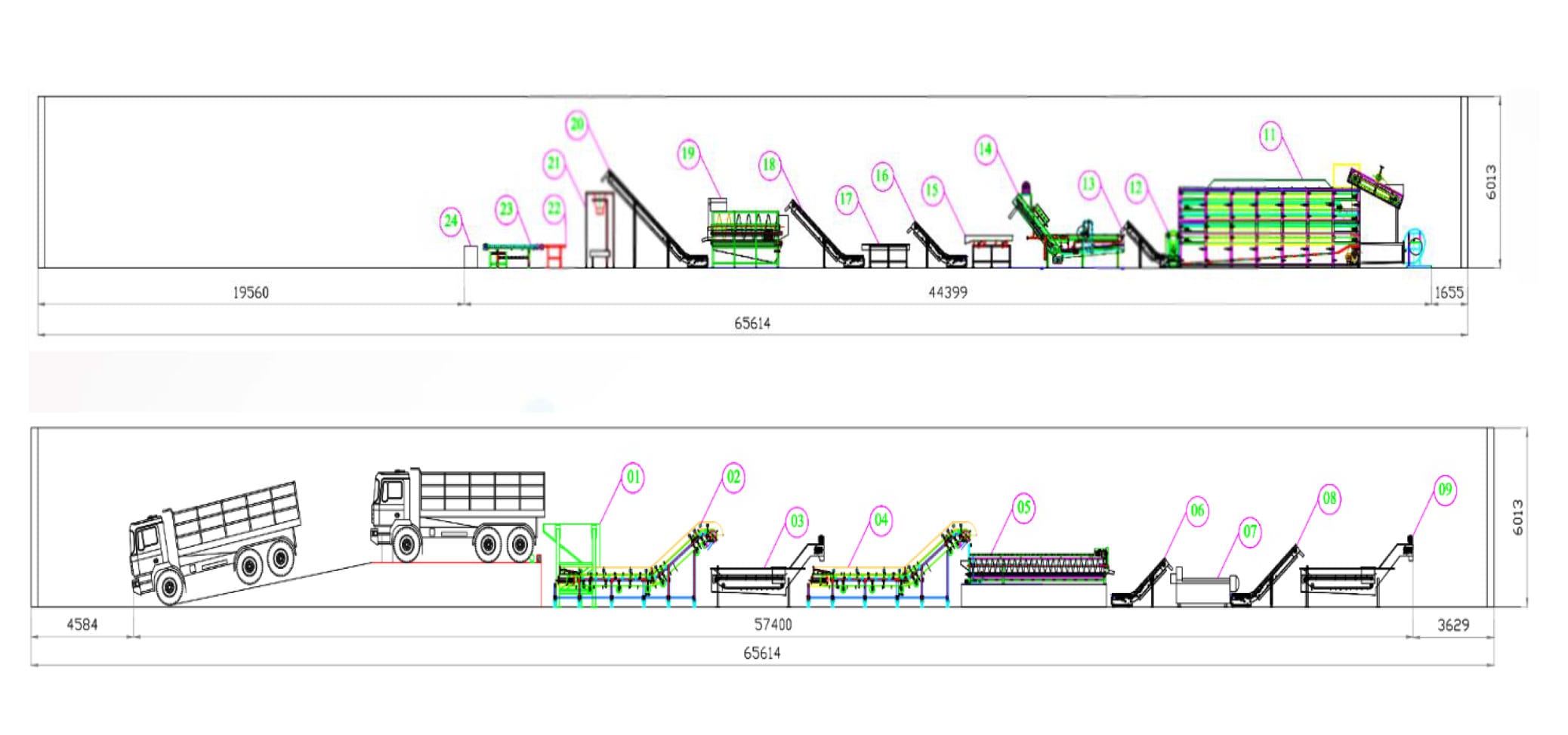

Cassava Flour Production Line

GEM Foodtech specialises in manufacturing and exporting highly advanced Cassava processing machinery. Our machines are designed to meet the production requirements of Cassava Chips and Cassava Flour. We can also customise the capacity of our cassava processing plant equipment machineries & plants to to suit individual clients needs.

Basic Parameters of Cassava Flour

- Thickness: less than 2mm for coarse cassava flour and less than 0.6mm for fine cassava flour

- Moisture: 12-14% Max

- Viscosity: 700 – 1000cps

- Ash Content: 10 – 0.20 Max

- Acid Insoluble: 05 – 0.1 % Max

- Protein: 20 – 0.3 % Max

Why Choose Us?

If you are a business owner looking for a cost-effective way of processing Cassava Processing Plant, our processing plant can be a great choice.

For any business enquiries, you can contact us today and get a clear knowledge about the technical aspects of the plants.

Enquiry

Bubble Washer for Cassava

- Cassava washer is also fitted with a filtration tank to continuously filter and remove dirt from the roots.

- The capacity for the washer is 500-5000 kg/hr.

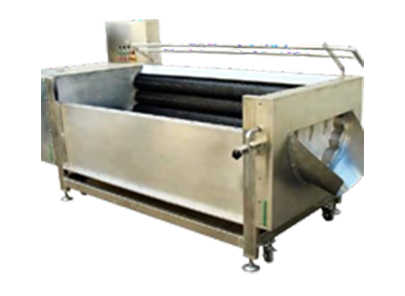

Peeling Machine for Cassava

- It is used for cleaning and peeling the Cassava.

- It removes dirt and an outer skin of Cassava.

- The machine is made of 304 food-grade stainless steel, which is beautiful, durable, and hygienic.

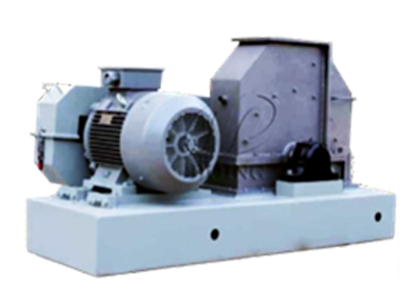

Cassava Rasper

- Cassava enters the Cassava Rasper machine through the upper feeding port and is crushed by the impact of high- speed saw blades.

- Food contact part is made of food grade stainless steel 304 which can ensure food safety.

- Special slot design to replace the assembly of saw blades

- The bottom sieve is designed with long strip holes, prevent material blocking.

Vibrating Dewatering for Cassava Flour Production

- The main parts of hydraulic vertical press machine are made of AISI 304.

- Hydraulic vertical juicing press machine offers the movable juice collector, easy to operate and confirm to the standards of

Fermenting Machine for Cassava Flour

- VFD / Mechanical Step pulley for change the residence time of the dhool.

- All drives with geared motor to ensure minimum loss of

- We can provide Zero-tracking mesh This is an optional feature.

- Automatic control on Humidification system for meeting changes of temperature and humidity.

- We can also provide a Steam Radiator with Actuators to raise the temperature of the fermenting bed, if This is an optional feature.

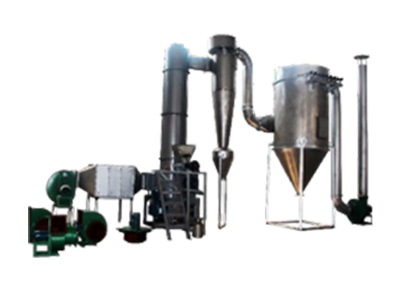

Flash Dryer for Cassava Flour

- Short retention

- Low product

- Cost effective and reliable with low maintenance and cleaning requirements.

- Backward curved radial blower for maximum efficiency & longer impeller life.

- High Efficiency Cyclone for minimum pollution & material

- Effective drying with low Energy (Fuel & Power)

- Appropriate for a wide range of

- Capacity: 250 Kgs/hr. to 2000 Kgs/Hr.

Cassava Chips Production Line

Basic Parameters of Cassava Chips

- Thickness: 2-4

- Bulk density before drying: 800-900 kg/m3.

- Moisture before drying: 60-70%

- Moisture after drying: 10-20%.

- Final Product: Cassava

Bubble Washer

- Cassava washer is also fitted with a filtration tank to continuously filter and remove dirt from the roots.

- The capacity for the washer is 500-5000 kg/hr.

Peeling Machine for Casava

- It is used for cleaning and peeling the Cassava.

- It removes dirt and an outer skin of Cassava.

- The machine is made of 304 food-grade stainless steel, which is beautiful, durable, and hygienic.

Cassava Chips Slicer Machine

- The MoC of the machine is SS304

- The function of the machine is to slice Cassava into Chips.

- The capacity of the machine is 500 kg/hr to 1500 kg/hr.

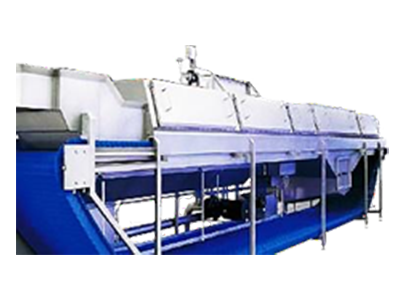

Belt type Blancher

- The belt-type blancher is used to blanch

- The capacity of a blancher is 500 kg/hr. to 3000 kg/hr.

- The MOC of the machine is

Mesh Belt Dryer for Cassava Chips

- Modular construction for easy assembly and

- AERODYNAMICAND INSULATED PLENUMCHAMBER for uniform fluidization.

- Stainless Steel grid plates with Stainless Steel Trays and Chains ensure hygienic standards across all food processing

- High efficiency Axial Flow Fans for exhausting humid

- Capable of drying small as well as larger particles

- Automation through PLC possible * UNIFORM FEEDING AND DISCHARGE with the help of Feed Conveyors and

- Capacity: 200 Kgs/hr. to 3000 Kgs/hr.

Band Dryer for Cassava Chips

- Modular Construction

- Different Heating Zones

- Variable Drying Time

- Controls and Instrumentation with PLC / HMI

- Optimum Capacity and highly efficient.

- Capacity: 200 Kg/hr. to 5000 Kgs./hr.