Pineapple is a tropical fruit native to the Amazon Basin in Brazil. Nowadays, it is cultivated across most tropical countries. Rich in vital minerals like vitamins B and C, Citric Acid, and Fructose, it is one of the most popular nutrition supplements.

The Popularity of Pineapple:

The rich flavour and the presence of multiple nutrients have made pineapple a common ingredient in many consumable items. This promotes the need to process the pineapple in various forms. From canning the fruit to making juice, you can use a pineapple processing plant to perform all activities.

Vital Steps of Pineapple Juice Extraction:

Extracting juice from a pineapple is an elongated process. Packaging it into a container also involves a few challenges. To explain the process better, we mention the most vital steps in sorting the fruit to remove the juice in bulk.

- Sorting the Pineapples: Fresh and juicy pineapples are the most suitable choice for juice making. Look for the fruits that have tender flesh and little fibres. Eliminate the unripe, rotten fruits and select the ones having 80% or more maturity. For easy sorting, you can place the pineapples in an automated sorting machine.

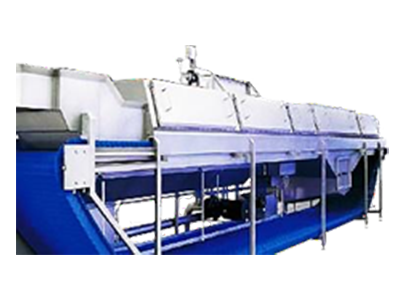

- Washing the Selected Fruits: In the pineapple juice processing stage, you cannot undermine the importance of washing. A brush and spray cleaning machine is the most suitable choice for cleaning the fruits properly. The machinery can help remove stains, impurities and pesticide residues efficiently.

- Peeling and Extraction: After fully cleaning the pineapples, place them in the peeling and extraction machine. In this process, the fruits are cut in half, and the peels and pulps are separated. The peeled pineapples are then transmitted to a spiral juice extractor. To make the most use of the juice, you can add water to the fruit residue for a secondary squeeze.

- Juice Packaging: Once you bring out all the juice from the fruit, it’s time for packaging. Remove all the suspended solids, fibres and colloidal particles first. Then, put the juice inside a vacuum degasser to remove the air bubbles. The next stage consists of cooling and sterilisation, which completes the juice packaging process.

To source fresh pineapple juice in bulk, it is important to follow these steps. Purchase a high-quality, functional pineapple processing plant for a smooth flow of the process. You can be assured of an easier juice extraction process that does not alter the fruit’s original nutritional values.