People love mango because it is the most rich tropical fruit in India that is rich in fat, protein, and sugar. It also includes vitamin, minerals and other high content of carotene. As one of the best tropical fruits, mango wins the hearts of fruit lovers. This is also known as the King of Tropical Fruits. Along with relieving thirst and fluid from the body, mango can prevent heat and vessel disease.

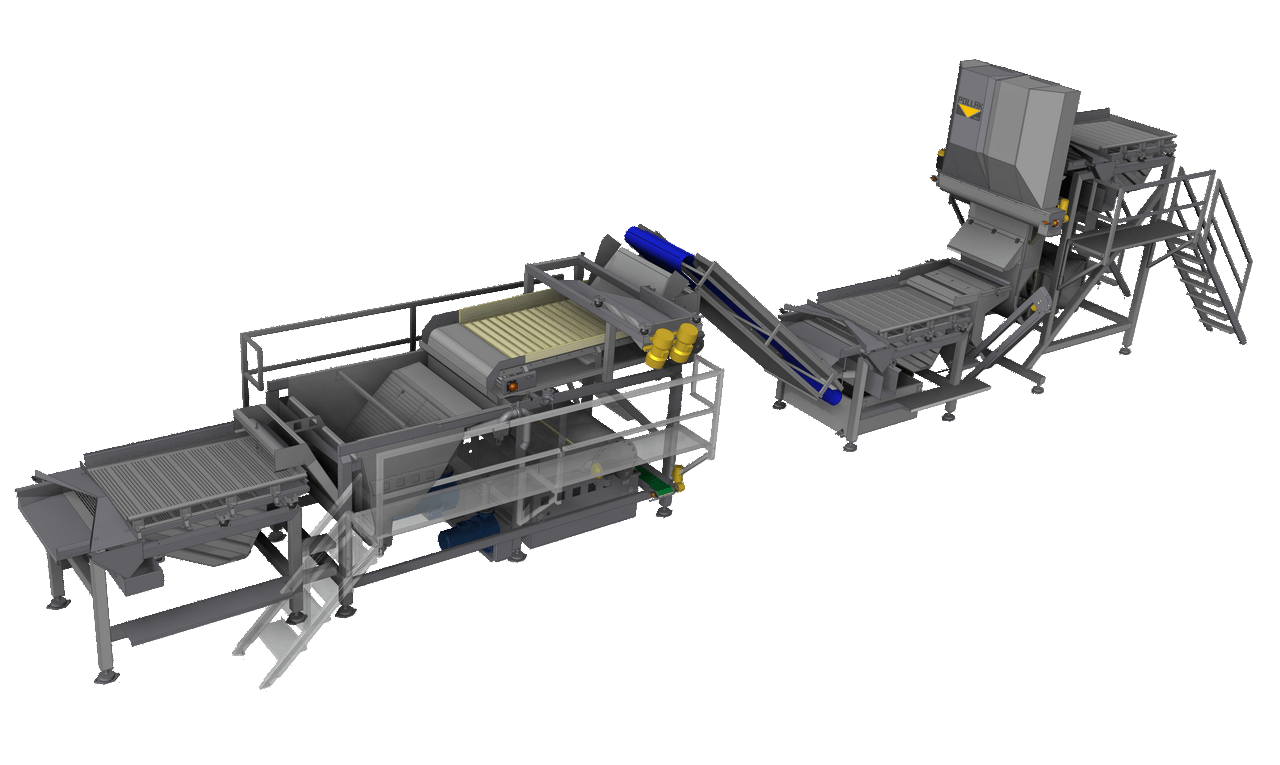

It can also moisten your skin. To manage the Mango Pulp Processing Line, a process is needed that can help in processing mango juice and pulp for deriving various products made of mango.

How does Mango Pulp Making Machine Works?

Mango can be processed in various types of products such as dried mango, mango juice, and mango pulp. Pulp processing is the most prevailing process to develop high nutrition products that are based on high yielding.

The mango pulp processing includes selecting, cleaning, pitting, peeling, pulping, pre cooking, concentrating, blending, sterilisation, filling, and cooling. The pre-treatment includes spray and brush cleaning, sorting, destoning, mango peeling, and other procedures.

Processing Flow of Mango Pulp

The mango customisation process involves the management of the exact functionalities on the basis of high-quality and high efficiency pulp maintenance. Have a look at the processing of mango pulp:

- Raw Material Treatment

In this process, you can separate qualified, superior, and defective mangoes with the help of the fruit sorting machine. For making mango pulp, the acid and pectin content should be around 1%. If the raw materials do not reach the level, then the cleaning process can help in dealing with the pesticide and purification residue process.

- Mango Pulping

Under the centrifuging and crushing of mangoes, you can use the mango pulping machine that can help in forming the fluid form of the mangoes.

- Pulp Pre-Cooking Process

The crude mango pulp needs heating and softening the mango. The mangoes are cooked for 10 minutes at high temperature. When the colour becomes dark, then the processing is done.

- Blending with Batching

After the batching and the heating process, you can use the mango pulp with a certain proportion of batches added. It is important to increase the volume with agar, pectin, and citric acid to maintain the acidic content.

GEM Foodtech follows a mango pulp processing line to produce various products made of mangoes such as jam, jelly, pickles, juice, squash, etc.