Cashew Processing Machinery

Thriving on extensive experience, GEM manufactures state of the art cashew processing lines. Our processing plants are low maintenance, easy to handle and cost-effective. The capacity of our plants ranges between 50 kg/hour and 500 kg/hour. We produce cashews processing machines that go through rigorous quality checks and guarantee optimal performance for your cashew processing applications.

EnquiryCashew Process Flow Chart

BOILING

Raw Cashews Are Steamed Under Pressure To Soften The Shell. This Causes The Cashews Inside To Become Loose And Easier To Remove In Time

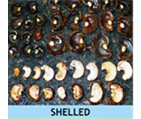

CUTTING

Each Cashew Shell Is Split Open Longitudinally And The Cashew Inside Is Immediately Taken Out By Hand

DRYER

The Skin On Cashews Is Dried In An Oven At Low Heat For A Few Hours To Loosen The Skin

HUMIDIFIER

Humidifier To Make The Kernels Up To 4.0 To 5.0 % Moisture Condition For Better Peeling Of Skin

PEELING

The Skin Of Each Cashew Is Removed By The Machine And The Cashew Is Simultaneously Visually Graded According To Quality

GRADING

The Whole Cashew Kernels Are Individually Graded By Machine According To Count Per Pound

COOKING SYSTEM

Capacity: 1000 Kg Raw cashew / Batch Steam cooker with steam generator wood fire complete set valves, gauges, meter, chimney and necessary fittings.

AUTOMATIC CASHEW SHELL CUTTING MACHINE (Four Cutter)

- Capacity: 40 – 50 kg/hr.

- Gear Motor Power: – 1 HP Phase – Three

- Number of cutters: – 4 No’s

- All parts in MS and Aluminium.

CONVEYOR SYSTEM FOR CASHEW NUT PROCESSING

To carry the material after shell cutting to scooping line.

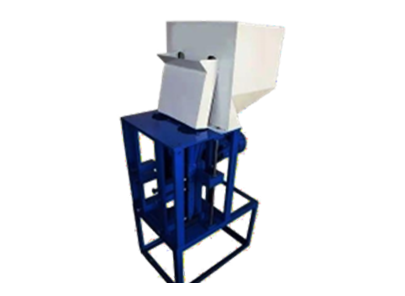

VIBRATOR (Automatic Total Scooping Solution) FOR CASHEW PROCESSING

- Capacity: 300-350kg/hr.

- Power : 5 HP

- Vibrator ( SS ): 2 No’s

- Shell Blower: 2 No’s

- Scooping Machine: 1 No’s

- Blower: 1 No’s

- This system is to be used after the cashew cutting / shelling

- Vibrator separates the removed cashew kernels

- Shell Blower separator the Uncut, half cut and

- The cashew after shelling is separated into empty shells, cashew kernels, uncut and half cut.

- With this system lot of manual labor can be eliminated for sorting.

- The sorting efficiency is very

- The manual process of sorting after shelling can be eliminated.

Batch Dryer for Cashews

To dry the Kernels of 500 Kgs at 55-60O C in 5 to 6 Hours.

- of Trays: 100 No’s

- Tray Size: 32” x 16” x 1 ¼”

- Electrical Heaters: Electrical 1KW heaters 16 No’s

- Motor: 2 HP 3 Phase – 2 no’s

HUMIDIFIER ROOM WITH EXTRA TRAYS AND TROLLEY

Humidifier to make the kernels up to 4.0 to 5.0% moisture condition for better peeling of skin.

- Extra trays (200 No’s)

- Trolley – 6 no’s

- All Tray in Food Grade

CASHEW NUT PEELING MACHINE

Cashew Nut Peeling Machine is used to remove the Red Skin of Cashew.

- Capacity: – 80-90 Kg/Hr.

- Material: – All Parts in SS

AIR COMPRESSOR

- Power: 15 HP

- Type: Screw Air Compressor Air Compressor is used to Blow the Air in the Peeling Machine to remove the Red Skin of Cashew.

Note: Which is suitable for 1 No’s of peeling machines.

KERNEL SEPARATOR (THREE GRADES)

To separate wholes, Half’s, Splits and Testa.

- Voltage Rating: – 415 V (Three Phase).

- Gear Box Motor Power: – 0.25 HP.

- All Parts in

FINISHED CASHEW GRADER

Power consumption: single Phase A/C 102 watts.

Number of Grading: Six (6).

PIECES GRADING MACHINE

Mechanized vibratory sieve with screens of SS mesh to separate the LUP, SWP, BB grades.

BRICKS VACUUM PACKING

T Shaped vertical vacuum packing Chamber

Size: 650 X 8mm bi-active pump

CUTTING TABLE WITH TWO CUTTERS

One Table with holding one cutter. (Hand operated)

- MOC: – MS

- Blades: – SS

GRADING TABLE FOR CASHEW PROCESSING

Size: 72’ L x 2’ w x 2.5’ H.

Top made of SS 202. The vertical & Horizontal support frames of the table made of MS.